Summary

Service Type

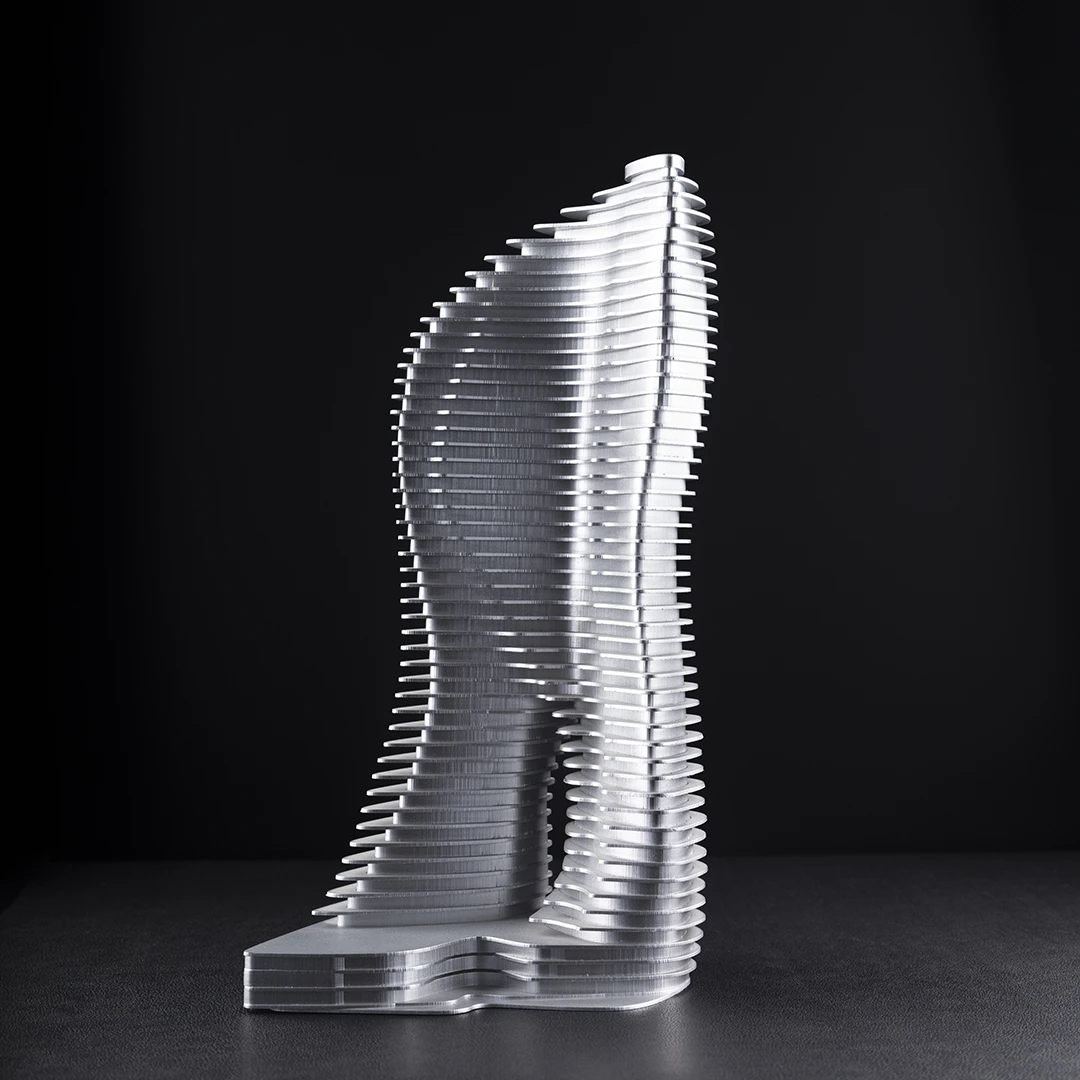

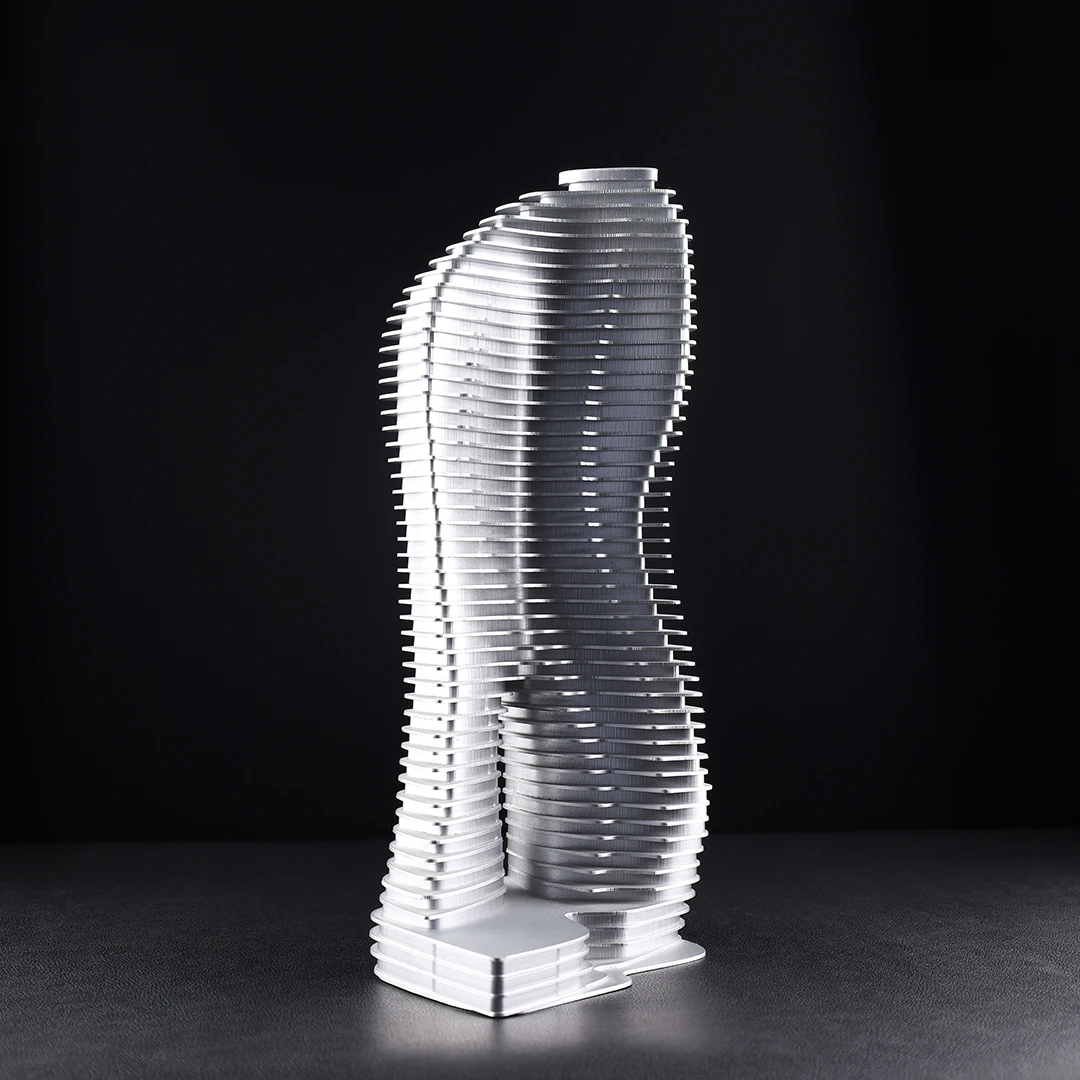

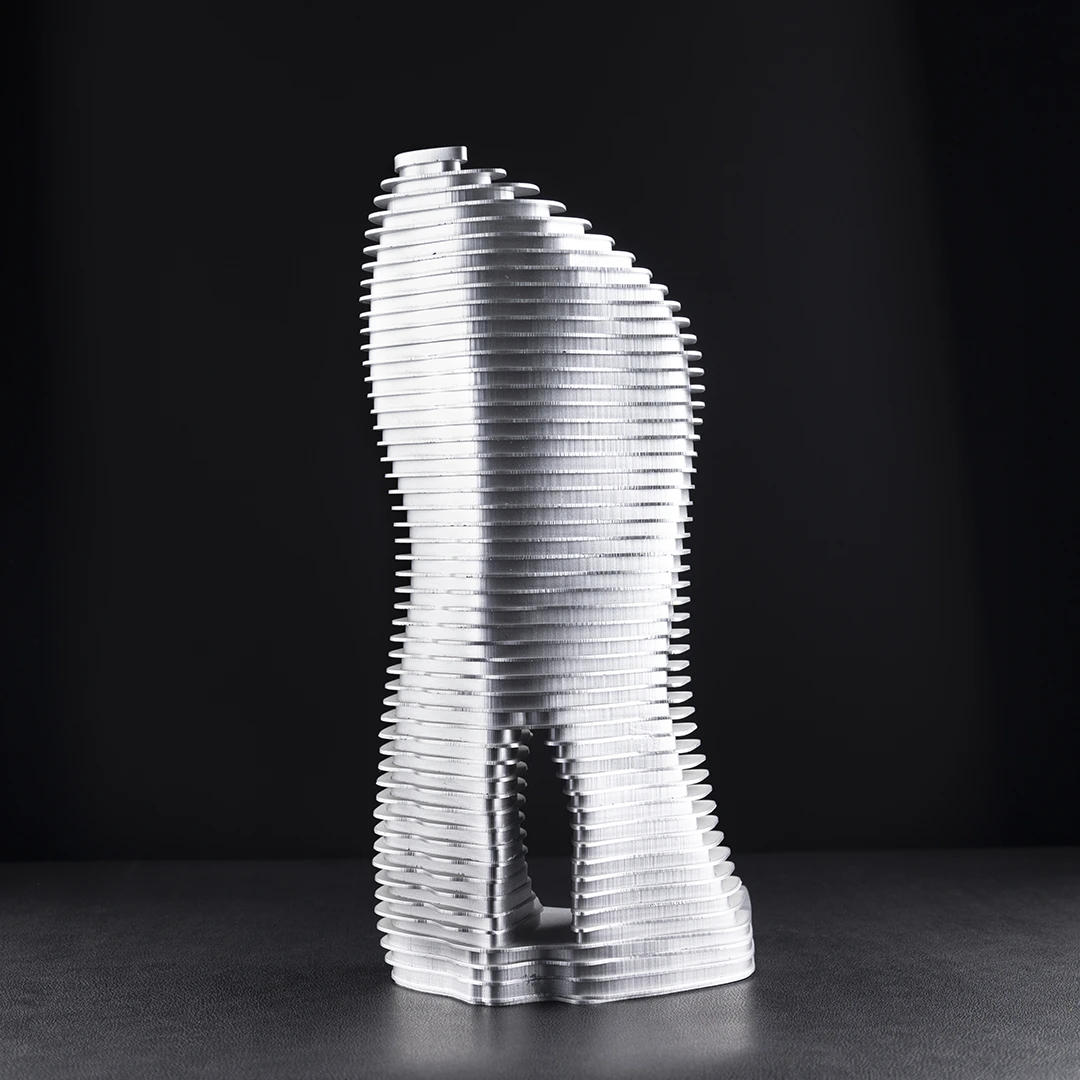

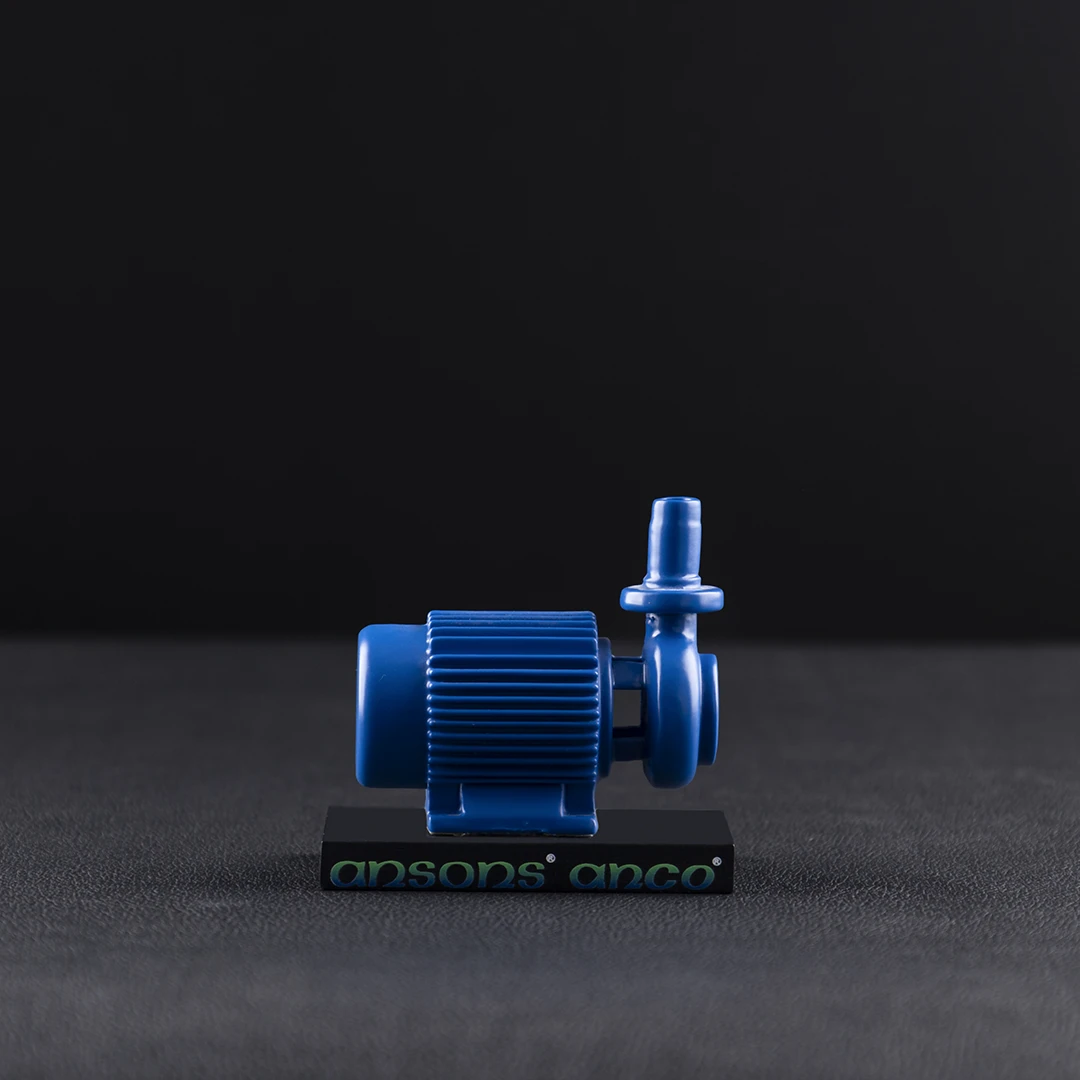

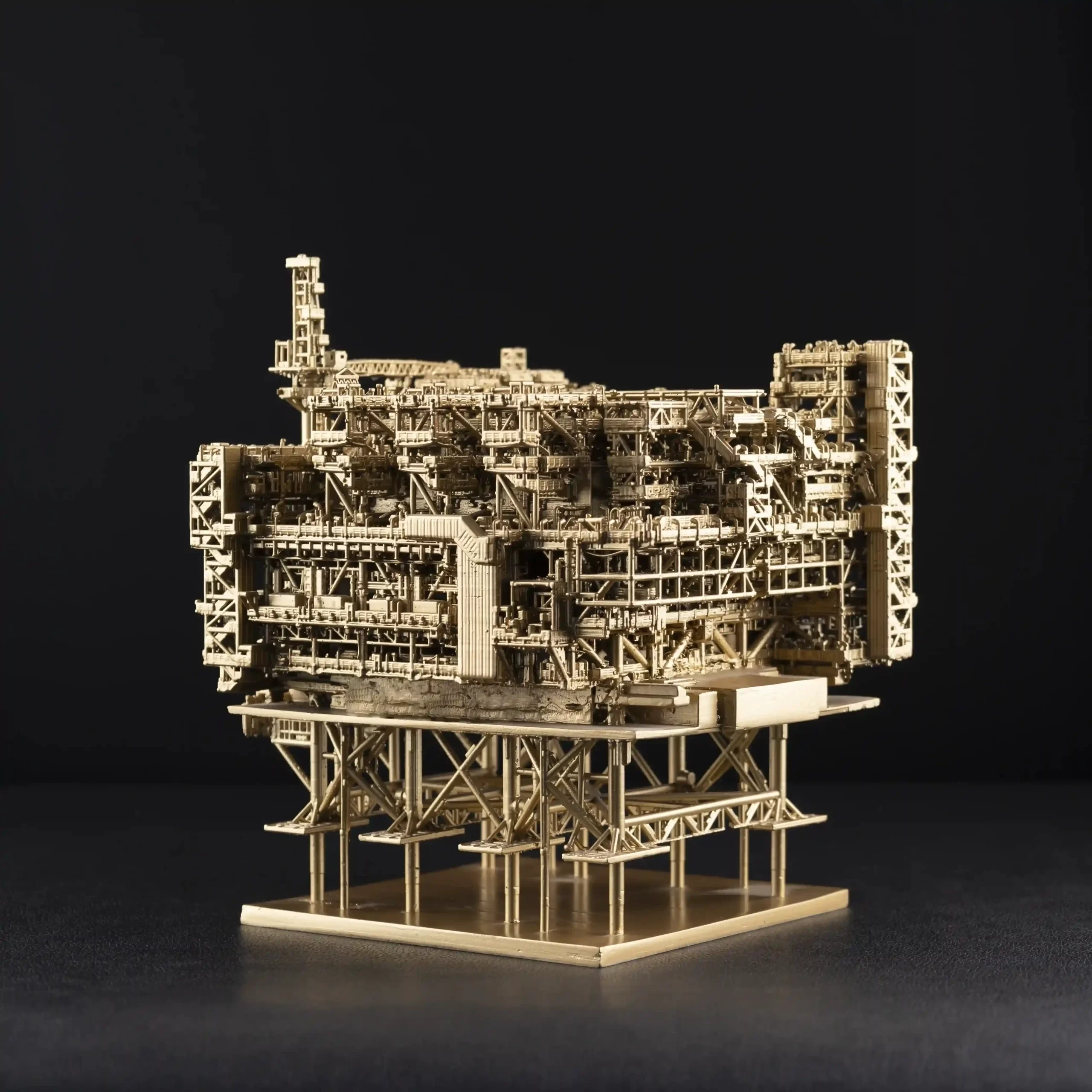

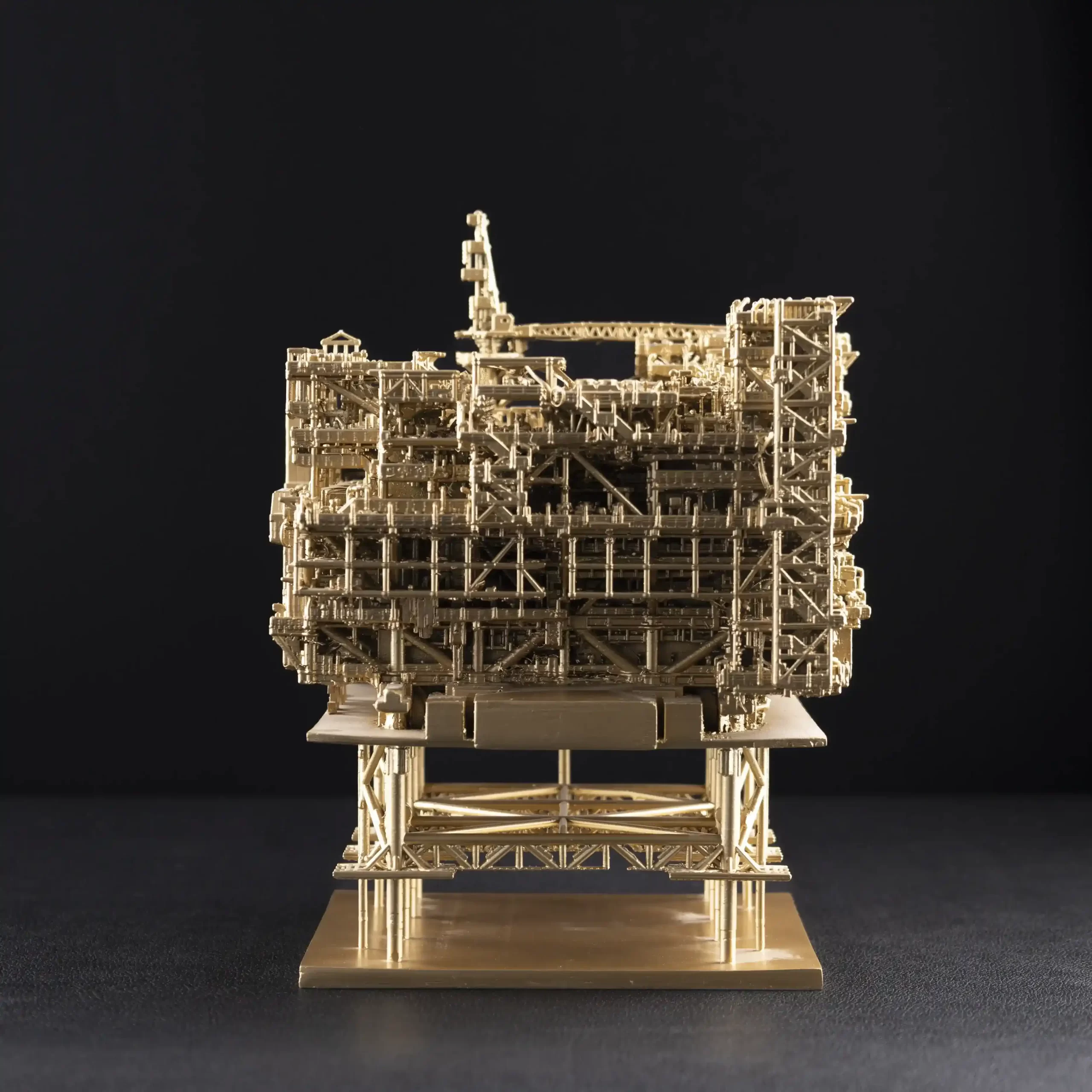

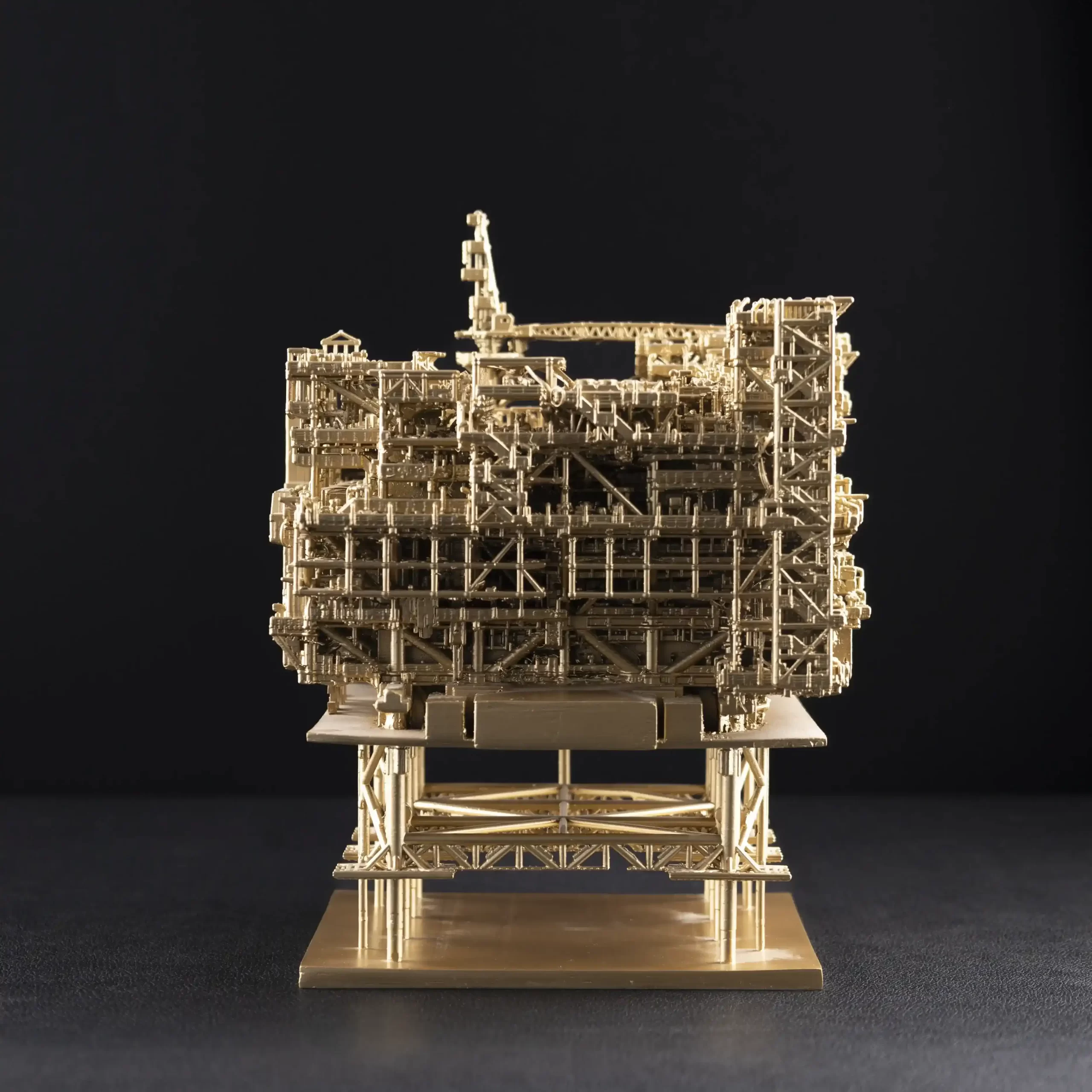

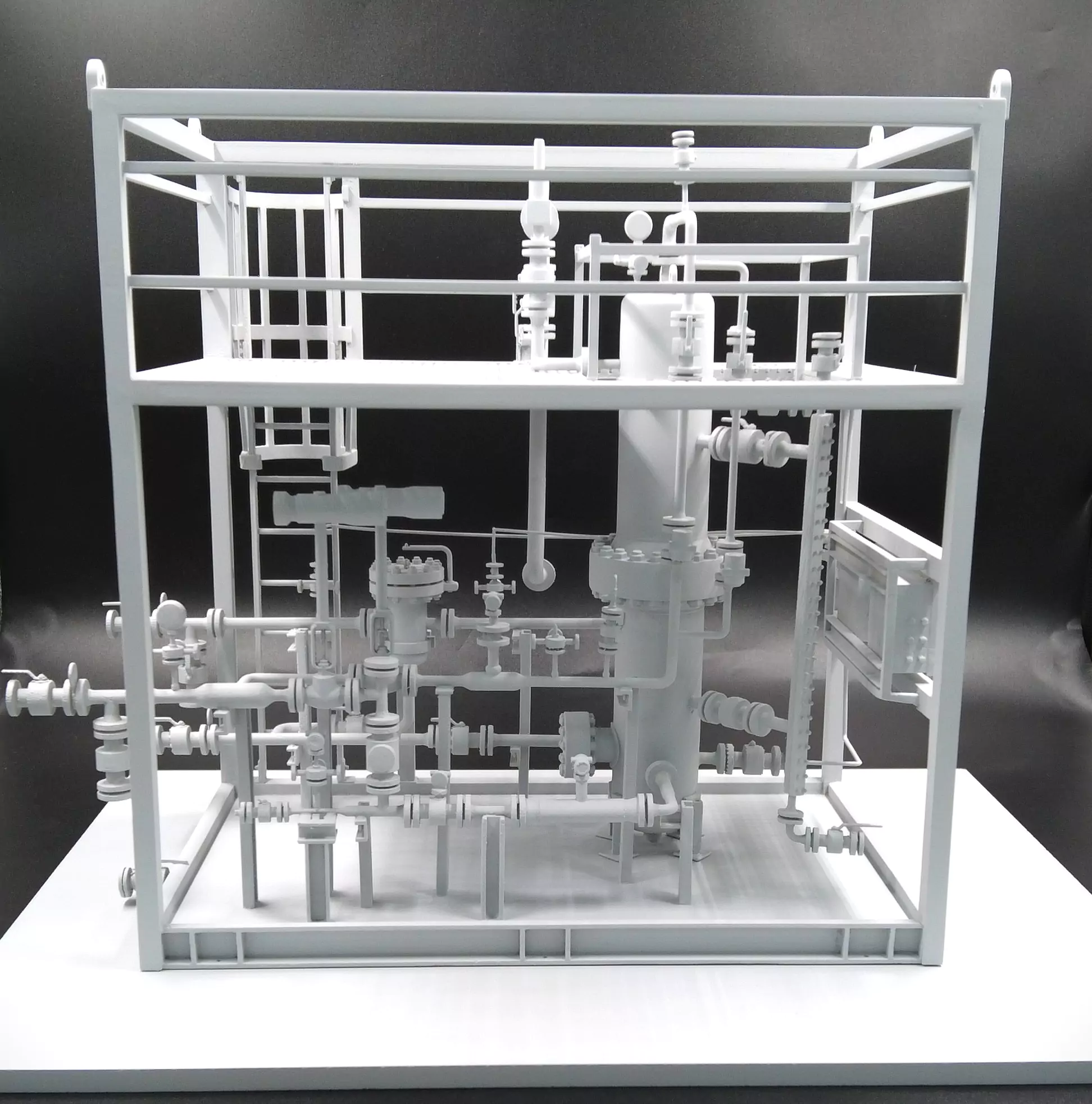

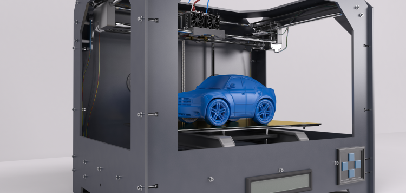

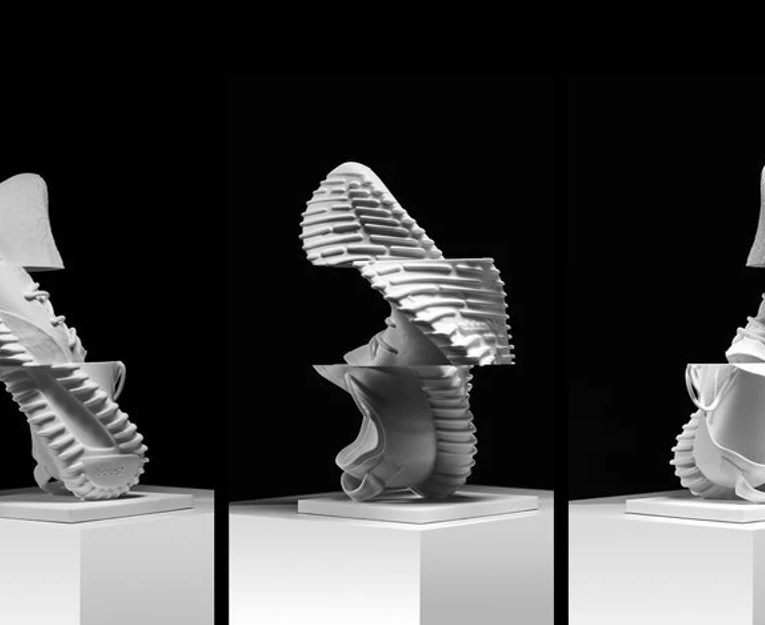

3D Printing

Provider Name

Crystal Corporation LLC,

32St,Ras Al Khor Industrial Area 2,Dubai, UAE-5277,

Telephone No.+971 4 326 6333

Telephone No.+971 4 326 6333

Area

Dubai

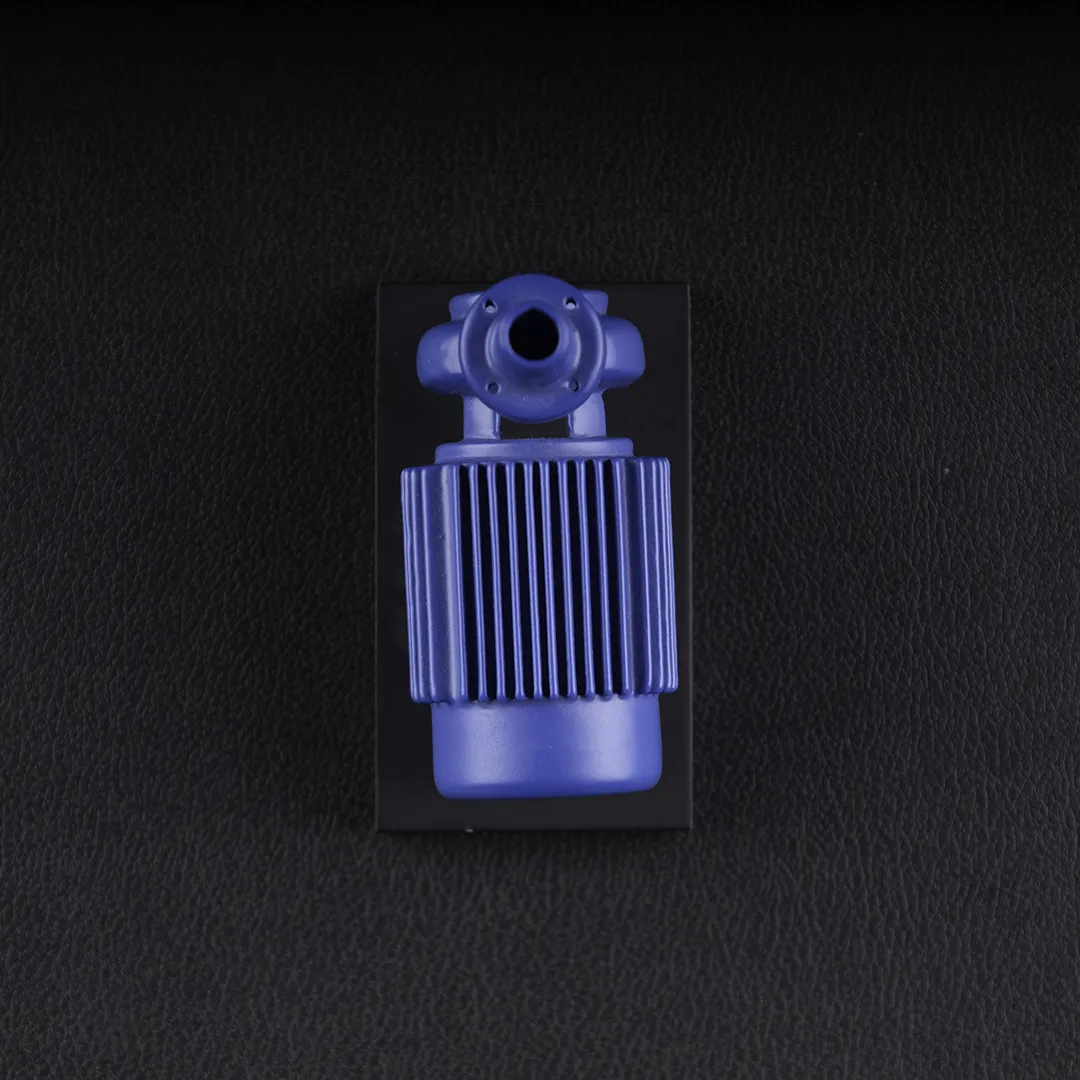

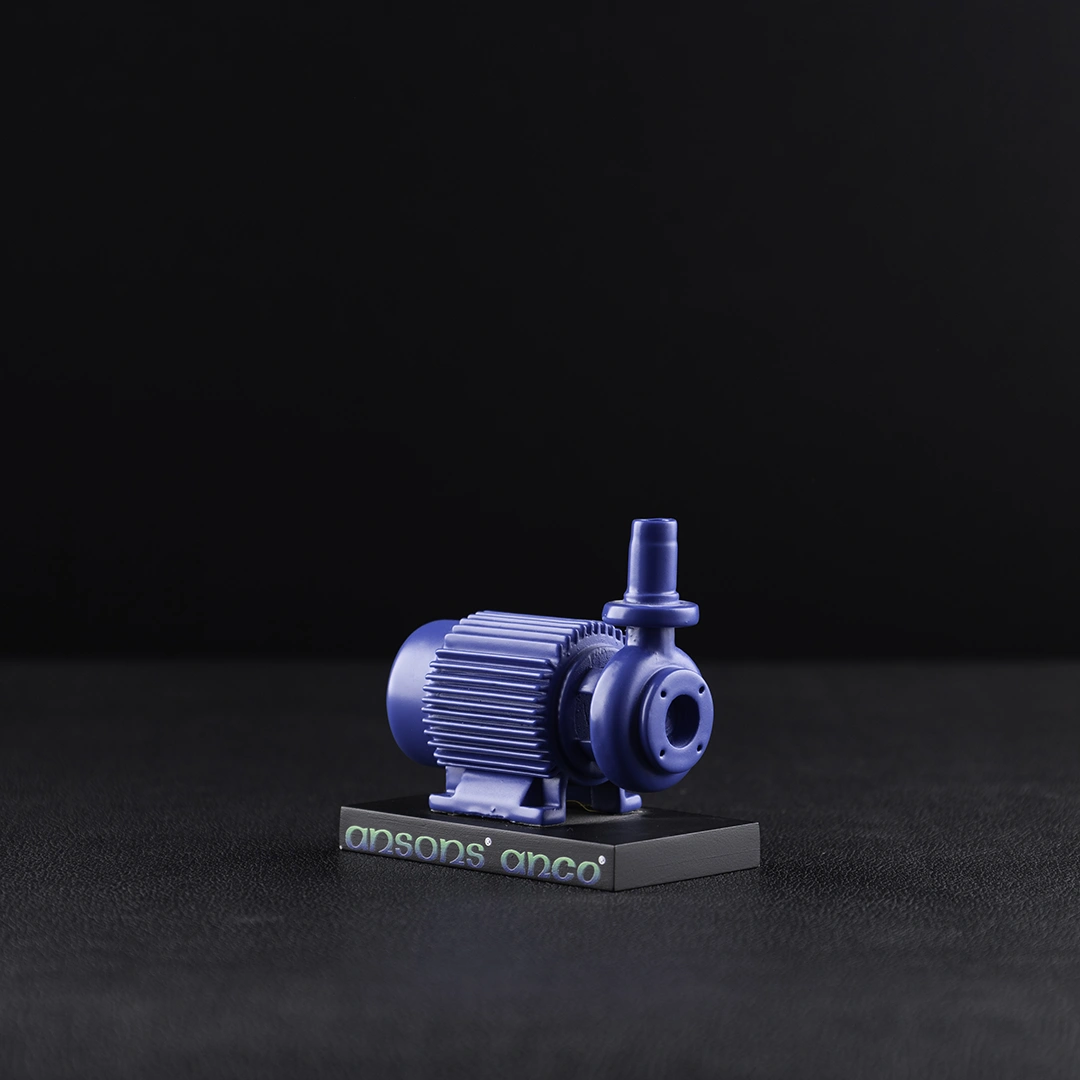

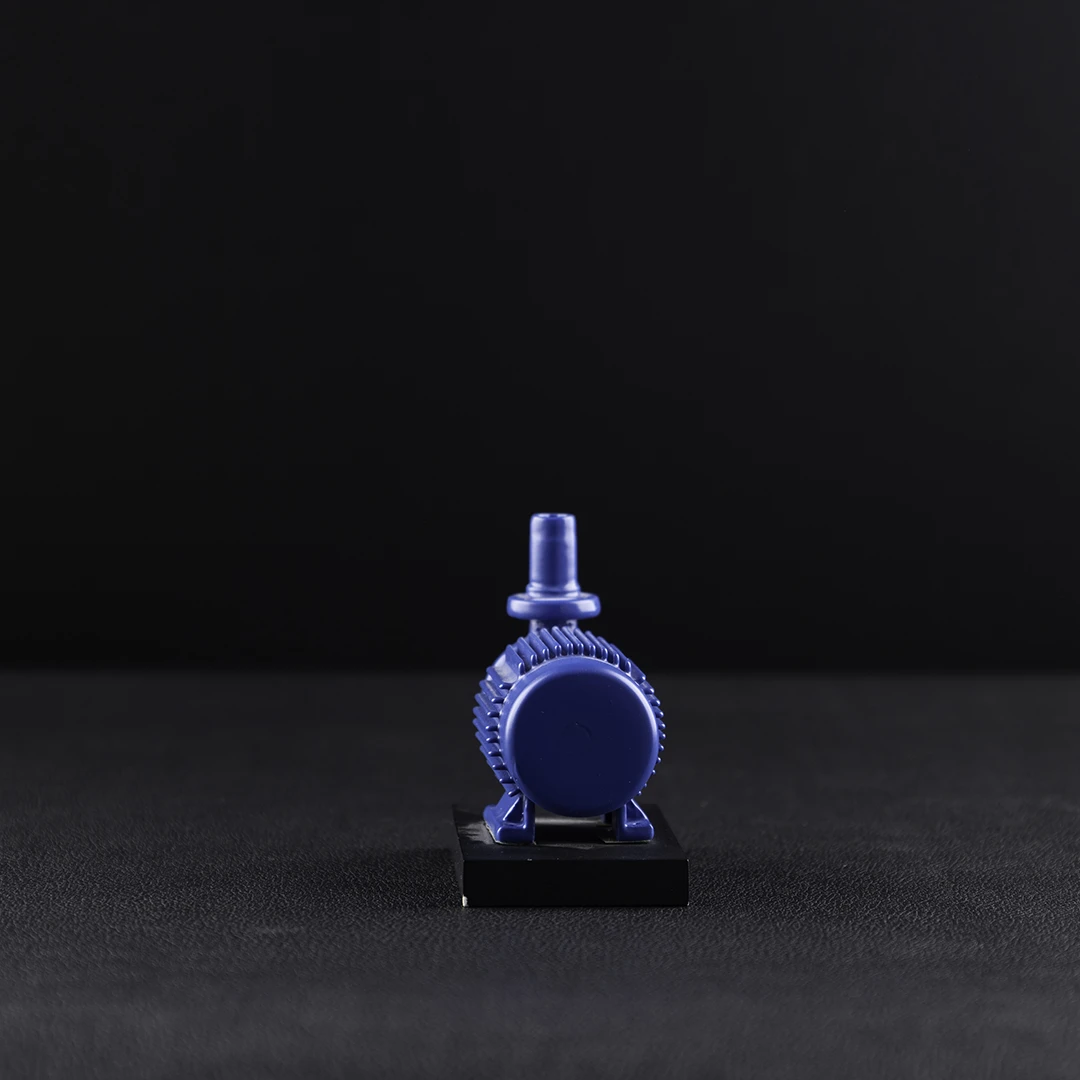

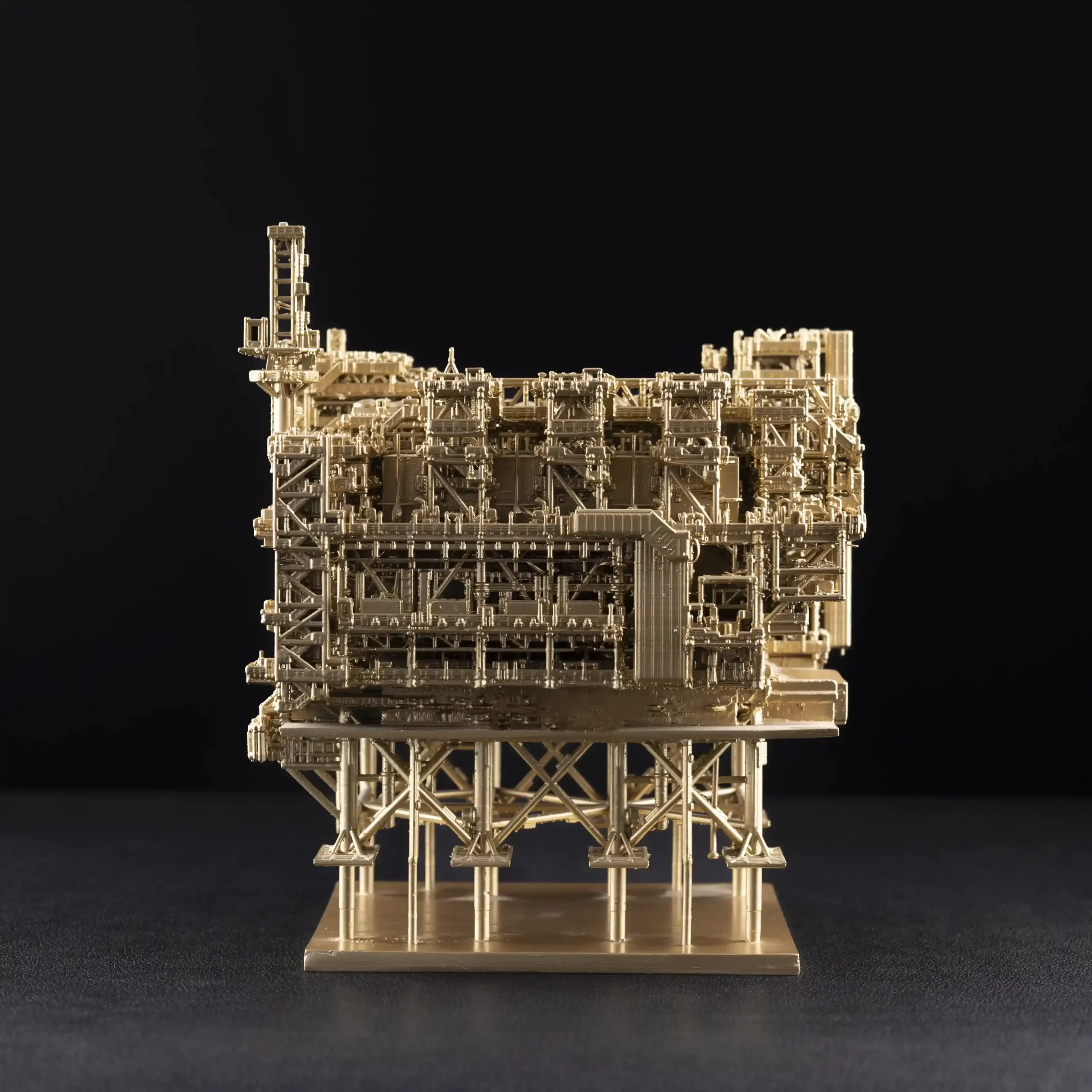

Description

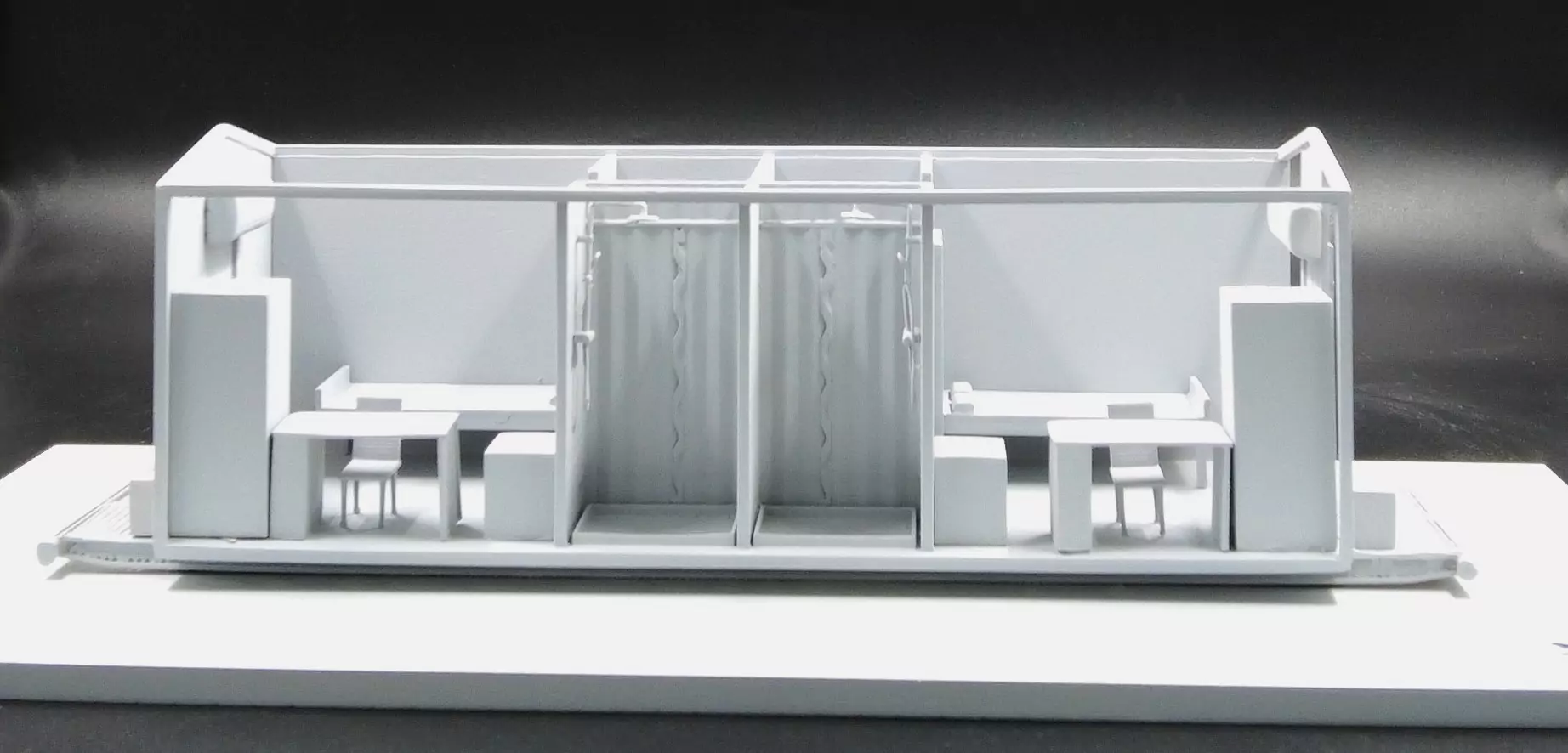

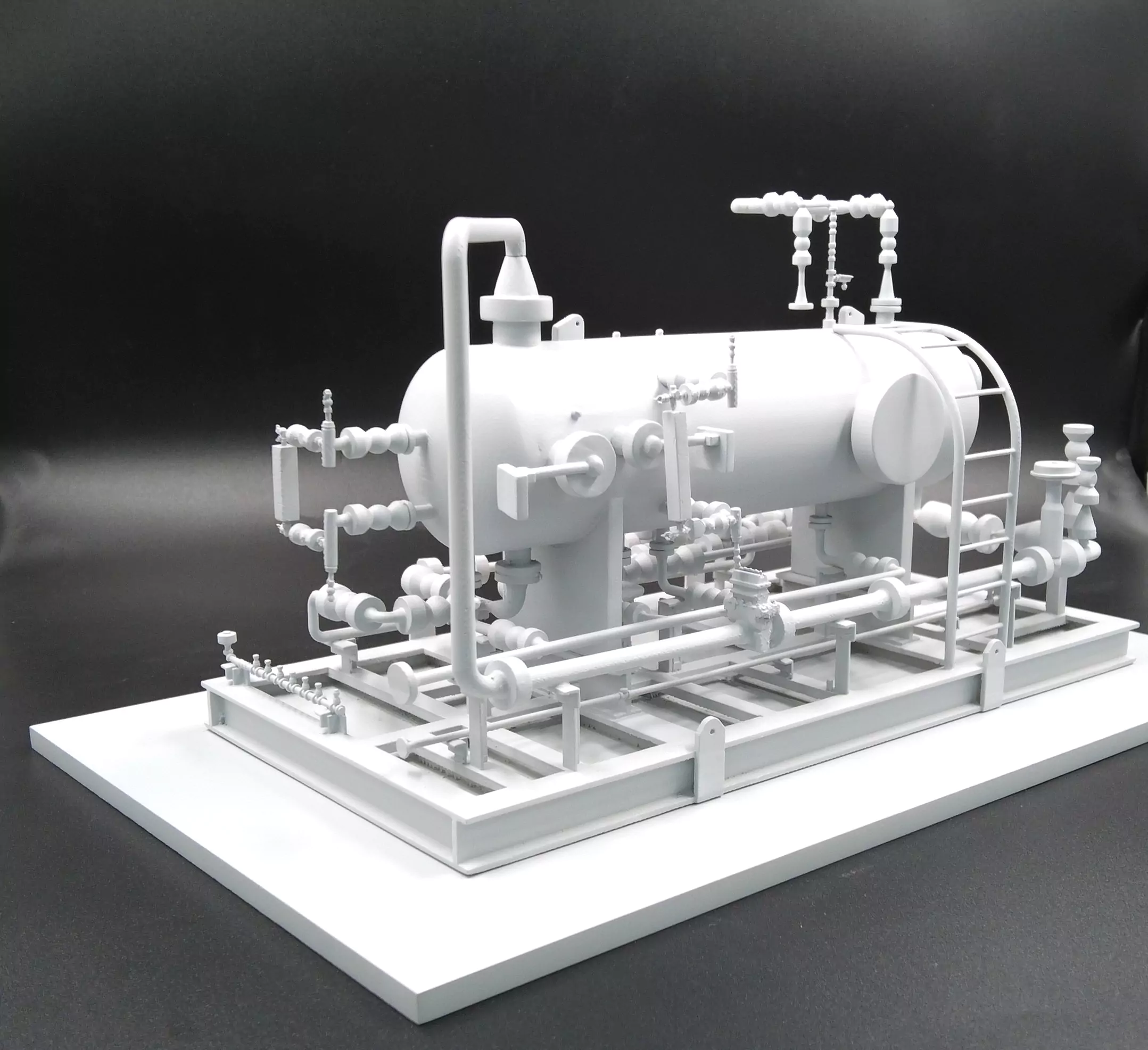

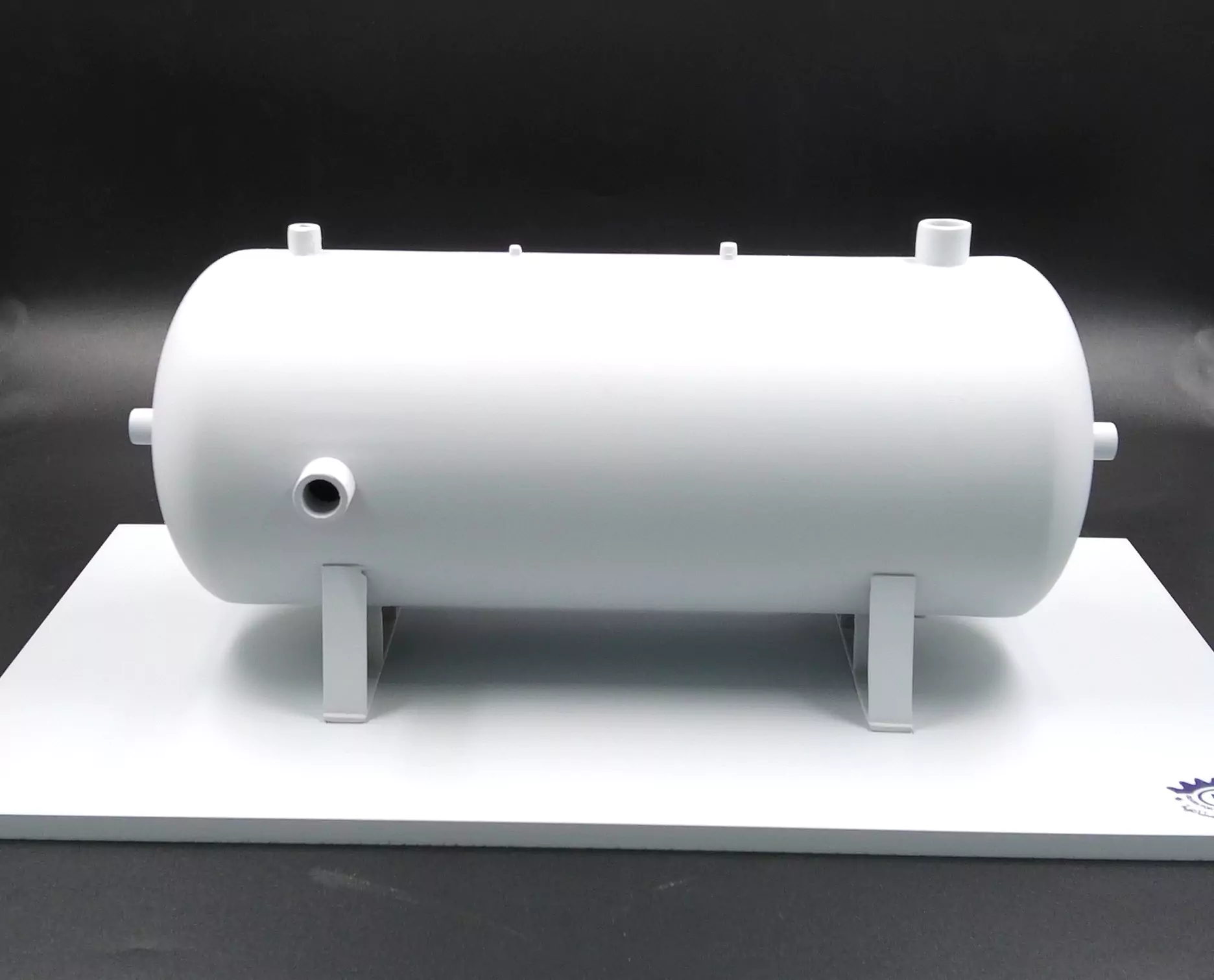

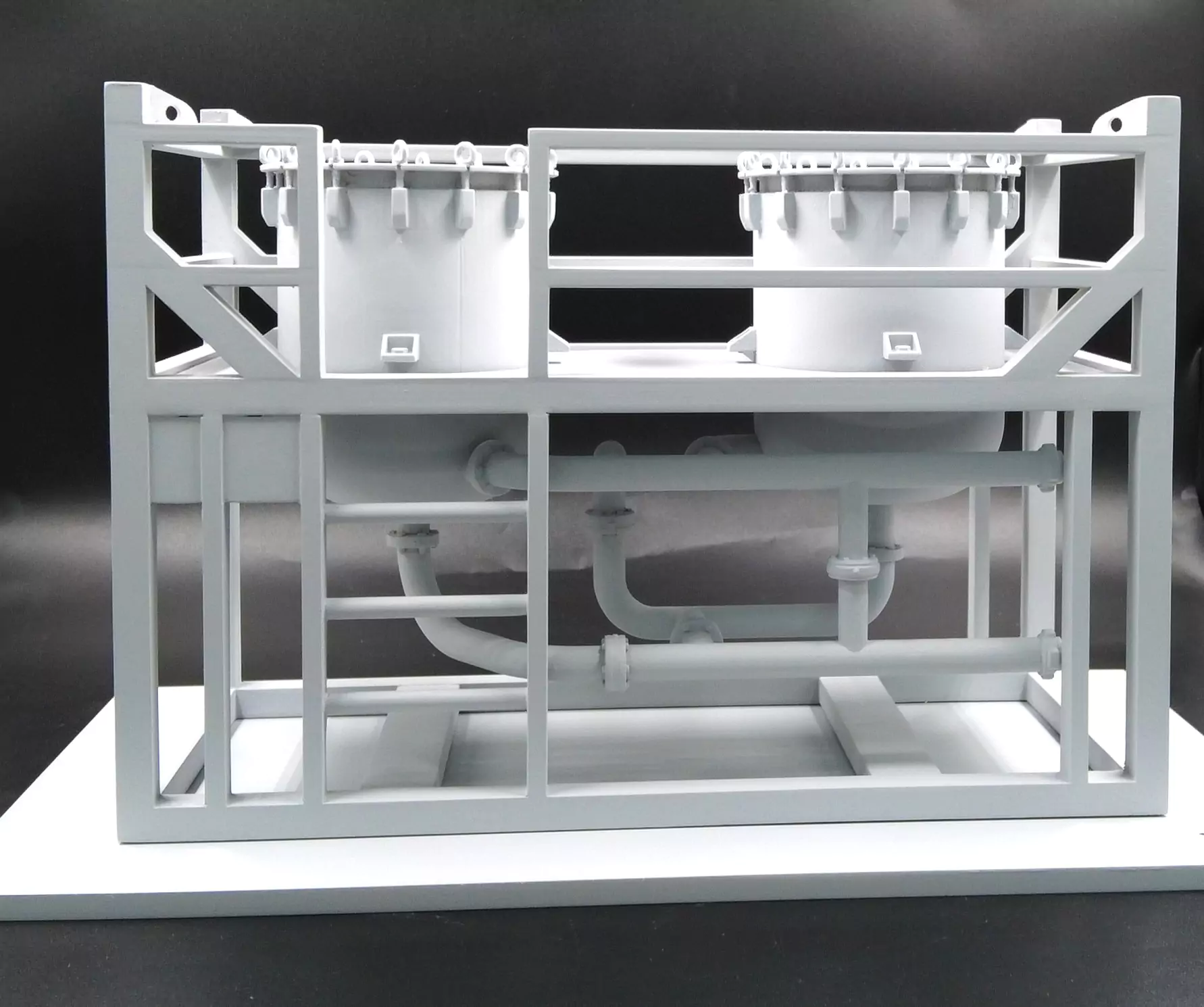

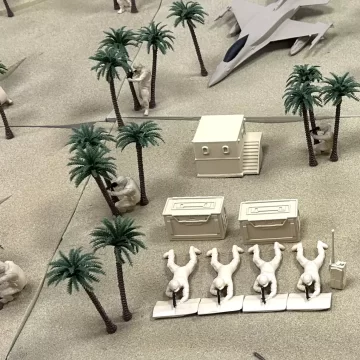

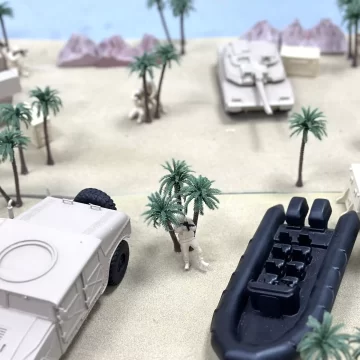

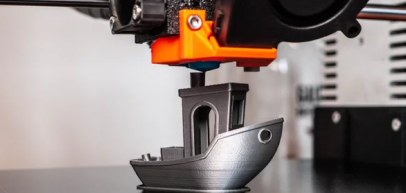

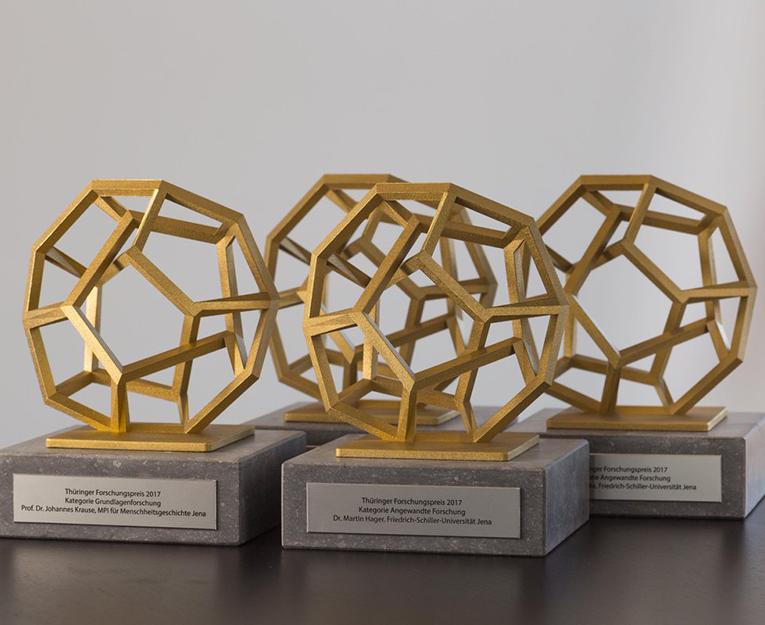

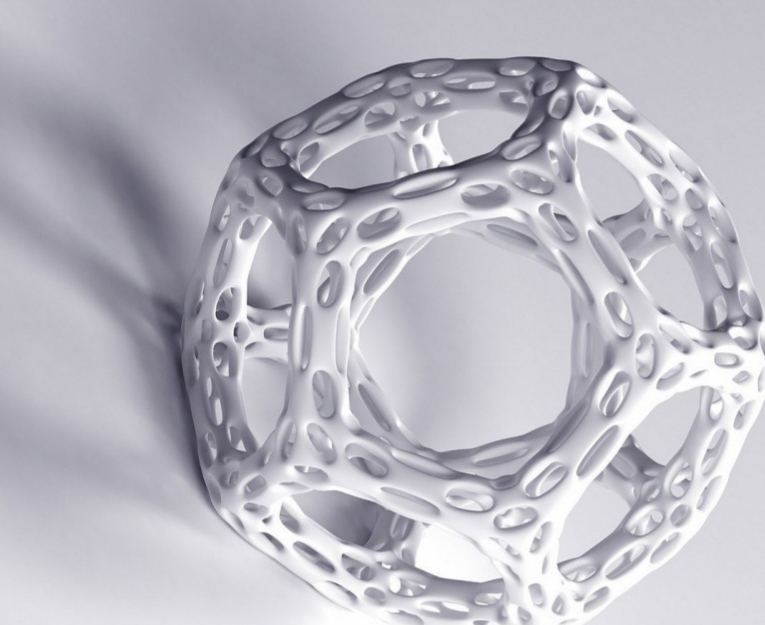

Unlock limitless possibilities with our cutting-edge 3D printing services in Dubai. As a trusted 3D printing company in UAE, we bring your ideas to life with precision and innovation. Whether you need 3D printing for models, prototypes, or customized designs, our advanced technology ensures unmatched quality and efficiency. Explore our expertise in 3D printing Dubai for architectural models, industrial designs, and creative projects. Transform your vision into reality with the leading 3D printing service provider in the region.