Selecting the right material for your 3D printing project is crucial for achieving the desired quality, durability, and functionality. With options like PLA, ABS, resin, and metal, each material has unique properties that make it suitable for specific applications. Whether you’re partnering with 3D printing companies in Dubai, using 3D printing services, or exploring options at a 3D printing company in Dubai, this guide will help you make an informed decision.

Understanding 3D Printing Materials

Each 3D printing material has distinct advantages and is tailored to meet various needs, from rapid prototyping to creating durable parts. Here’s a breakdown of the most popular options and when to use each:

- PLA (Polylactic Acid)

Properties: PLA is a biodegradable thermoplastic derived from renewable resources like corn starch or sugarcane. It’s environmentally friendly, easy to work with, and emits low fumes, making it a favorite for beginners and experienced users alike.

Benefits: PLA is one of the easiest materials to print with, which makes it ideal for simple, non-load-bearing parts and rapid prototyping. It offers a smooth finish and vibrant color options.

Ideal Applications: PLA is commonly used for models, decorative items, and quick prototypes. Due to its low heat resistance, it is not suitable for high-stress or outdoor environments.

Best for: Beginners and creative projects needing a quick, affordable solution.

- ABS (Acrylonitrile Butadiene Styrene)

Properties: ABS is a robust, durable thermoplastic that’s commonly used for industrial applications. While it requires higher print temperatures, ABS is known for its impact resistance and ability to withstand higher temperatures compared to PLA.

Benefits: ABS is highly resistant to wear and tear, making it ideal for functional parts that need to withstand more demanding conditions. Its flexibility also allows for some post-processing adjustments, such as sanding and painting.

Ideal Applications: ABS is often chosen for automotive parts, electronic housings, and tools due to its toughness and flexibility.

Best for: Durable, functional parts that need to withstand moderate stress.

- Resin

Properties: Resin is a liquid material used primarily in SLA (Stereolithography) and DLP (Digital Light Processing) 3D printing. Resin prints provide high-resolution detail and smooth finishes but are generally more brittle compared to thermoplastics like PLA and ABS.

Benefits: Resin materials excel in creating intricate and detailed prints, often with a smooth, glossy finish. Specialized resins, such as flexible or heat-resistant types, expand the range of possible applications.

Ideal Applications: Resin is perfect for intricate models, jewelry, dental models, and any project requiring fine detail.

Best for: High-detail models and artistic applications.

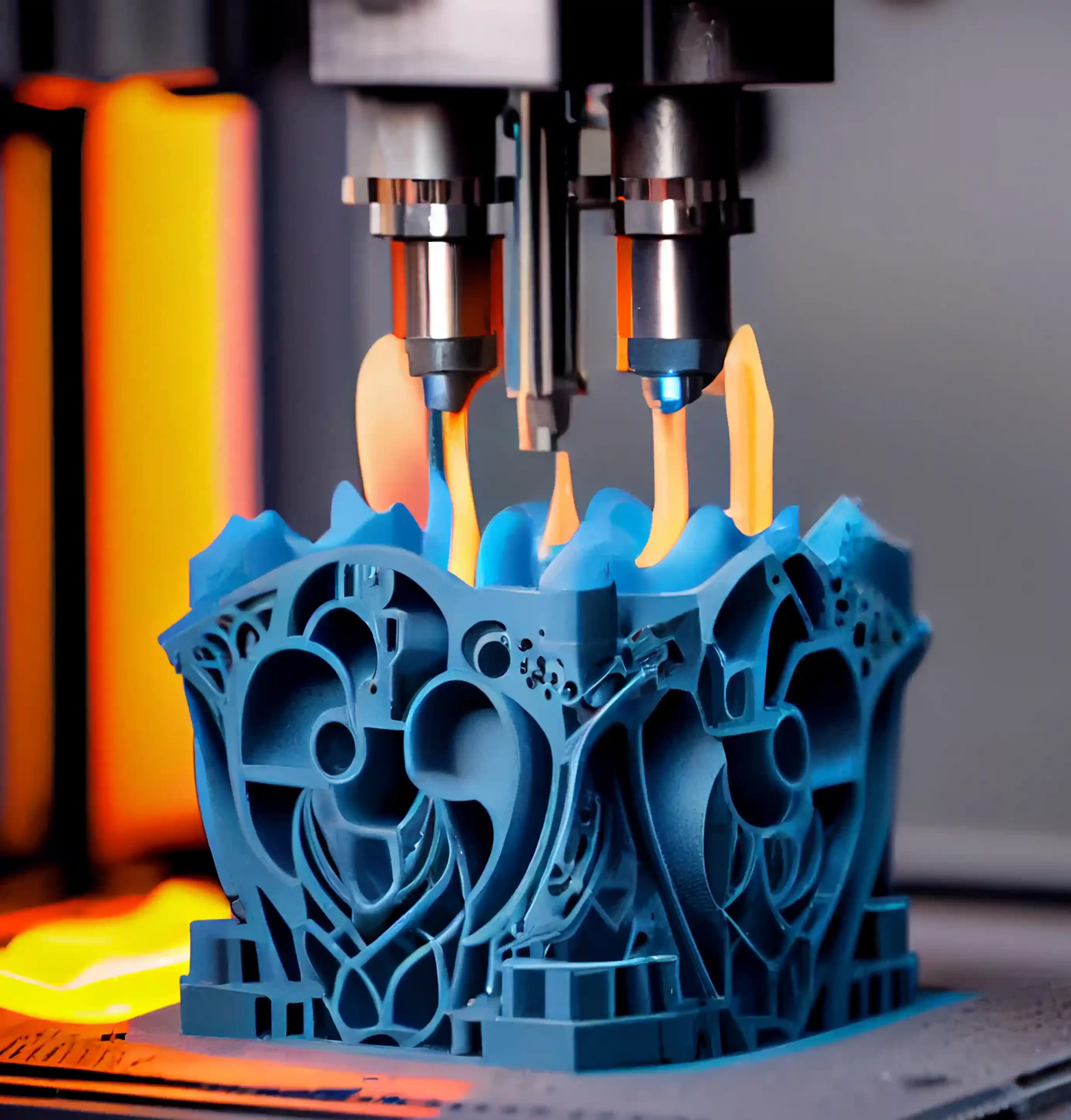

- Metal

Properties: Metal 3D printing involves metal powders that are fused through high-energy processes, such as selective laser melting (SLM) or electron beam melting (EBM). Metal prints are extremely durable, resistant to high temperatures, and suitable for heavy-duty applications.

Benefits: Metal materials provide exceptional strength and durability, making them suitable for functional parts in industries like aerospace, automotive, and medical. Metal 3D printing also allows for the production of complex geometries that would be challenging or impossible with traditional metalworking.

Ideal Applications: Metal is best for parts exposed to high stress, such as machine components, custom tools, and aerospace parts.

Best for: High-strength, high-temperature applications where durability is essential.

Choosing the Best Material for Your Needs

The decision depends on the requirements of your project. If you’re working with a 3D printing company in Dubai or using 3D printing services in UAE, consult with their experts to choose the most suitable material. Here are some key considerations to help narrow down your options:

Budget: PLA is typically the most affordable, while metal is the most costly.

Durability: ABS and metal are excellent for long-lasting, functional parts, while resin and PLA are better suited for less demanding uses.

Precision: For high-detail work, resin is the best option, followed by PLA.

Environment: Consider temperature and outdoor exposure – ABS and metal withstand heat and rough conditions better than PLA and resin.

Partnering with 3D Printing Companies in Dubai

Dubai’s 3D printing landscape has become a hub for cutting-edge technology and innovation. Many 3D printing companies in Dubai offer specialized services to meet diverse project needs, from prototyping to large-scale manufacturing. Whether you’re a small business seeking prototypes or a large company in need of intricate parts, 3D printing services in Dubai offer a wide range of options for every material.

For clients seeking flexibility, there are also 3D printing shops in Dubai that cater to smaller projects and custom orders. These shops provide a more personalized approach, which can be ideal for creative or unique projects.