The term sustainability is no longer just a buzzword in today's world; it's a necessity. As industries strive to reduce their environmental footprint, the trophy and awards industry is also embracing eco-friendly practices. One of the key technologies driving this shift is 3D printing, offering a range of environmental benefits in trophy manufacturing.

Let's delve into how 3D printing is revolutionizing the creation of eco-friendly awards, from reduced waste to energy efficiency and the use of recyclable materials.

Reducing Waste with Additive Manufacturing

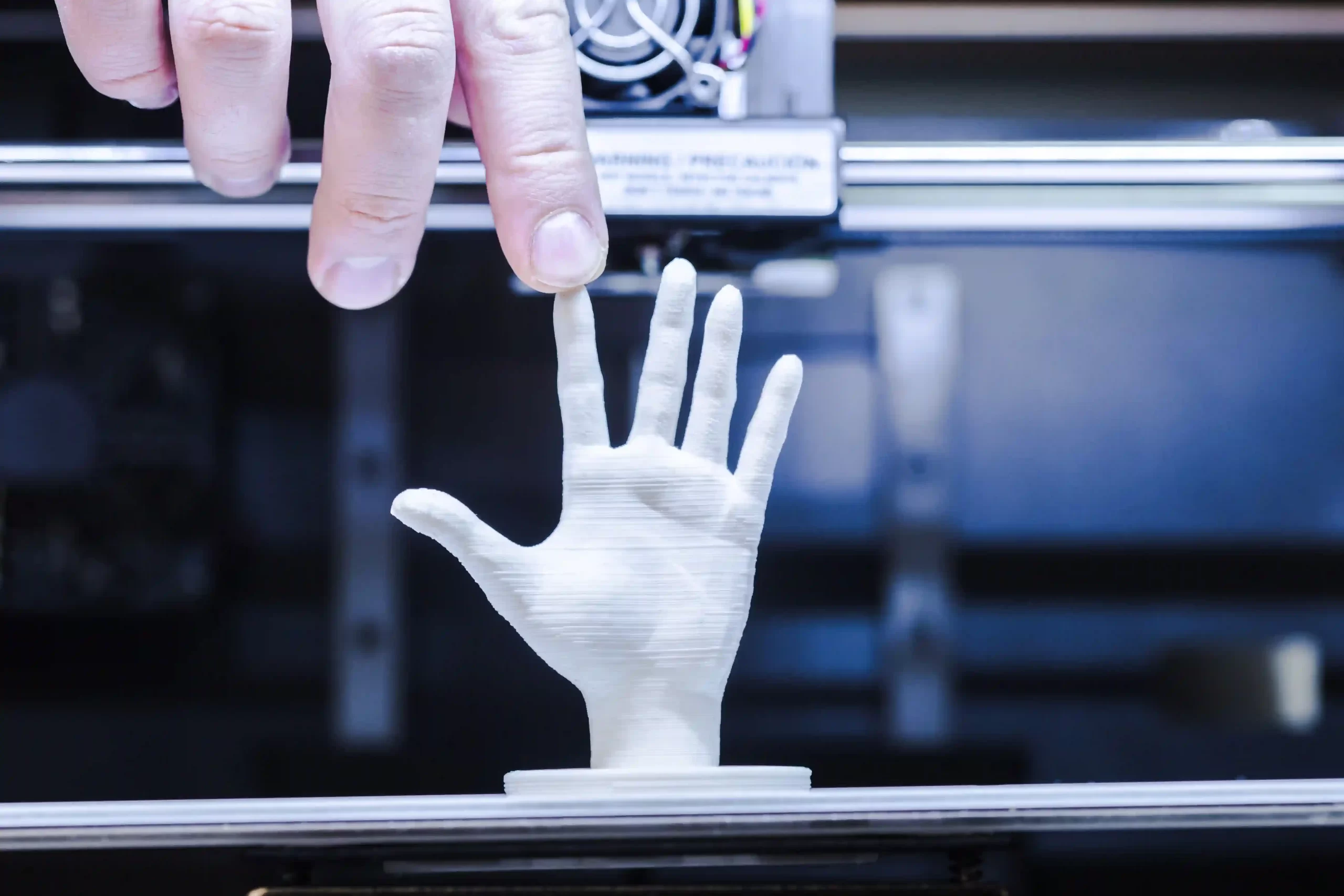

Traditional trophy manufacturing processes often result in significant material waste. Traditional methods like CNC machining or injection molding involve cutting away excess material from a solid block, leading to a substantial amount of scrap. In contrast, 3D printing, also known as additive manufacturing, builds objects layer by layer, using only the amount of material required for the design. This additive approach drastically reduces waste, making 3D printing a more sustainable choice for trophy production.

Energy Efficiency in Production

Energy consumption is another critical factor in sustainable manufacturing. 3D printing is inherently more energy-efficient compared to traditional manufacturing techniques. With 3D printing, energy is primarily used during the printing process itself, where the printer melts and deposits the material layer by layer. In contrast, traditional methods often require energy-intensive processes like cutting, shaping, and molding, which contribute to higher energy consumption and carbon emissions. By opting for 3D printed trophies, companies can reduce their overall energy usage and environmental impact.

Utilizing Recyclable and Biodegradable Materials

One of the significant advantages of 3D printing is the ability to use a wide range of materials, including recyclable and biodegradable options. PLA (polylactic acid) and ABS (acrylonitrile butadiene styrene) are common materials used in 3D printing that are both recyclable and biodegradable, making them environmentally friendly choices for trophy production. These materials can be recycled and reused, further minimizing waste and promoting a circular economy approach to manufacturing.

The Role of 3D Printing Companies in Eco-Friendly Practices

3D printing companies play a crucial role in promoting sustainability in trophy manufacturing. By offering 3D printing services specifically tailored for awards and trophies, these companies enable businesses to adopt eco-friendly practices without compromising on quality or design. Customers can work with 3D printing experts to create custom trophies using sustainable materials, ensuring that their recognition programs align with their environmental values.

Leading the Way Towards Sustainable Recognition

As businesses and organizations increasingly prioritize sustainability, the demand for eco-friendly awards and trophies continues to grow. 3D printing is at the forefront of this sustainability revolution, offering a greener alternative to traditional trophy manufacturing methods. By embracing 3D printed trophies, companies not only reduce their environmental impact but also send a powerful message about their commitment to sustainability and responsible manufacturing practices

In conclusion, eco-friendly awards are no longer just a trend but a necessity in today's environmentally conscious world. 3D printing plays a vital role in making sustainable trophy manufacturing a reality, with benefits including reduced waste, energy efficiency, and the use of recyclable materials. As businesses strive to make a positive impact on the planet, choosing 3D printed trophies is a step towards a greener and more sustainable future.