The rapid evolution of 3D printing technology has opened doors to innovative possibilities, with one of the most exciting advancements being multi-material 3D printing. Unlike traditional single-material prints, this method allows the integration of multiple materials into a single print, creating objects with varying properties such as strength, flexibility, and color all at once. This capability is revolutionizing industries ranging from manufacturing and engineering to healthcare and fashion. This blog will explore how multi-material 3D printing works, its benefits, and its implications for various sectors.

How Multi-Material 3D Printing Works

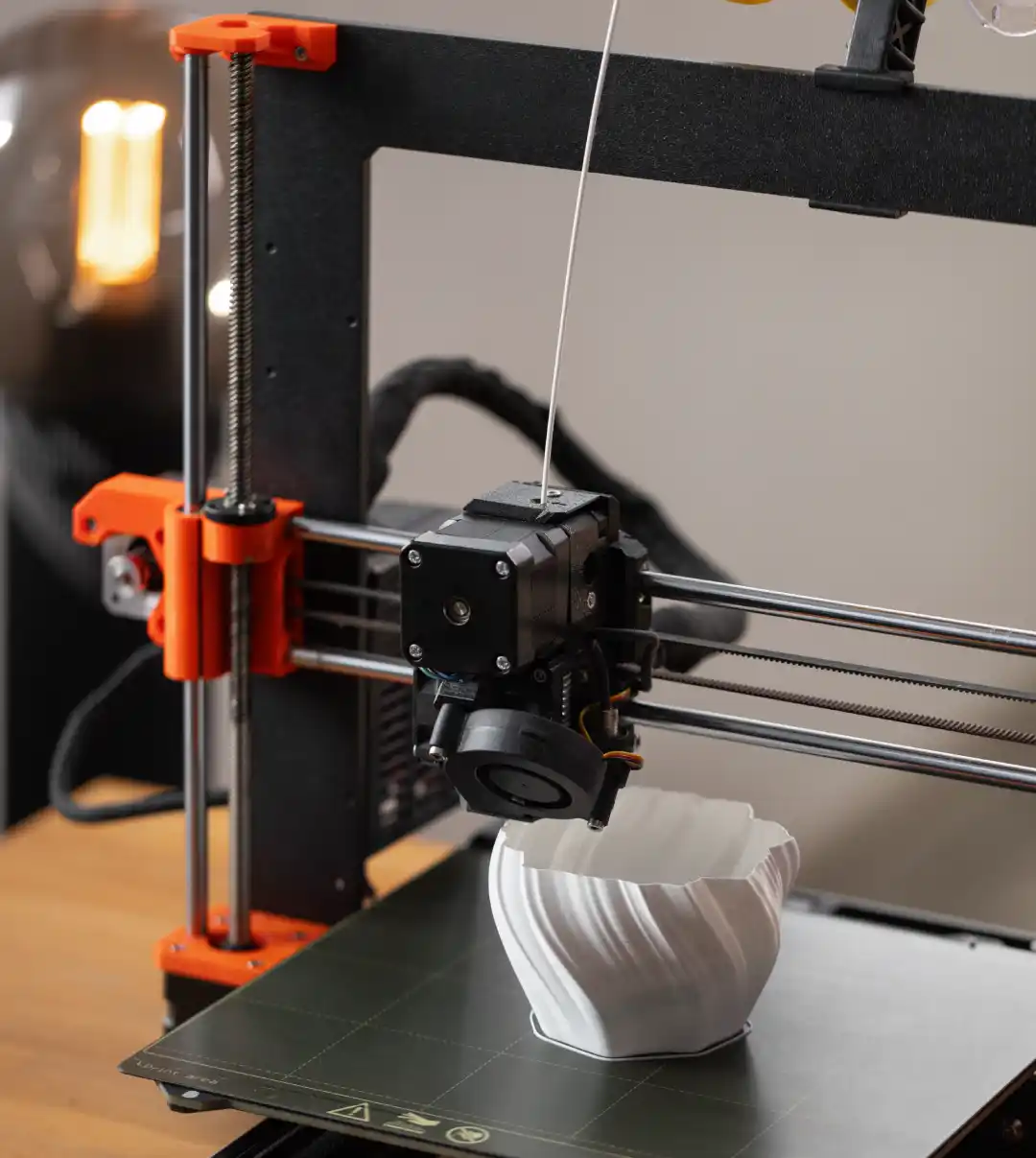

Multi-material 3D printing involves using specialized 3D printers with multiple extruders or material cartridges. These machines are designed to print with different materials—such as plastics, metals, and even ceramics—within the same object. By precisely controlling the deposition of each material, it is possible to create intricate designs with varied properties in one continuous process.

Benefits of Multi-Material 3D Printing

Enhanced Design Complexity

With multi-material 3D printing, manufacturers can produce intricate, multi-functional parts in a single production run. This is ideal for industries like aerospace, automotive, and robotics, where components often require a combination of properties such as heat resistance, flexibility, and strength.

Streamlined Production

Traditional manufacturing often requires multiple steps to combine different materials into a single product. Multi-material 3D printing eliminates these extra steps by producing the entire object in one go, significantly reducing production time and costs.

Cost-Effective Prototyping

Companies can develop highly detailed prototypes that closely mimic the final product without the need for expensive molds or assembly lines. This is especially useful for industries looking for fast iterations during product development, such as medical devices or consumer electronics.

Tailored Functionalities

In industries like healthcare, multi-material 3D printing is used to create custom prosthetics, implants, and surgical tools that are tailored to a patient’s specific anatomy. The ability to combine biocompatible materials with varying flexibility and strength ensures that the products meet exact functional needs.

Sustainability

Multi-material 3D printing can reduce waste by using only the necessary amount of each material, making the process more sustainable compared to traditional methods where excess material is often discarded.

Applications of Multi-Material 3D Printing

Aerospace and Automotive Industries

Multi-material printing enables the production of lightweight yet durable components that are essential for reducing fuel consumption. Complex parts like turbine blades, engine components, and airframes can be printed with high precision and strength.

Medical Industry

Custom medical devices such as prosthetics, hearing aids, and surgical tools benefit from the flexibility and precision of multi-material printing. For example, a single medical tool can be printed with a rigid structure for stability and a soft grip for ease of use.

Consumer Goods

Fashion, sports equipment, and wearable tech companies are exploring the possibilities of multi-material 3D printing to create products that are both functional and visually appealing, such as shoes with rigid soles and soft, flexible uppers.

Electronics

Multi-material 3D printing is being used to manufacture electronic components that integrate conductive materials with insulators, enabling the development of more compact and efficient devices.

Multi-Material

Dubai is quickly becoming a hub for advanced 3D printing technology. With the emergence of 3D printing companies in Dubai and specialized 3D printing services, businesses across the region are embracing multi-material 3D printing for a range of applications. Leading 3D printing companies in Dubai are now equipped with cutting-edge technology that allows the creation of highly detailed, multi-functional prototypes and end-use products. These advancements are accelerating innovation in sectors like architecture, healthcare, and manufacturing.

Whether you are a startup or an established company, 3D printing services in Dubai offer a wide range of solutions to meet your design and production needs. From 3D printing companies in Dubai to dedicated 3D printing shops, the technology is now more accessible than ever for companies across the UAE.

In conclusion, the economics of 3D printing are reshaping the manufacturing landscape, particularly in Dubai. By lowering costs, enabling customization, and opening new markets, this technology is creating a wealth of opportunities for businesses and individuals alike. As 3D printing continues to mature, its impact on the economy will only grow, leading to a more innovative and sustainable future.