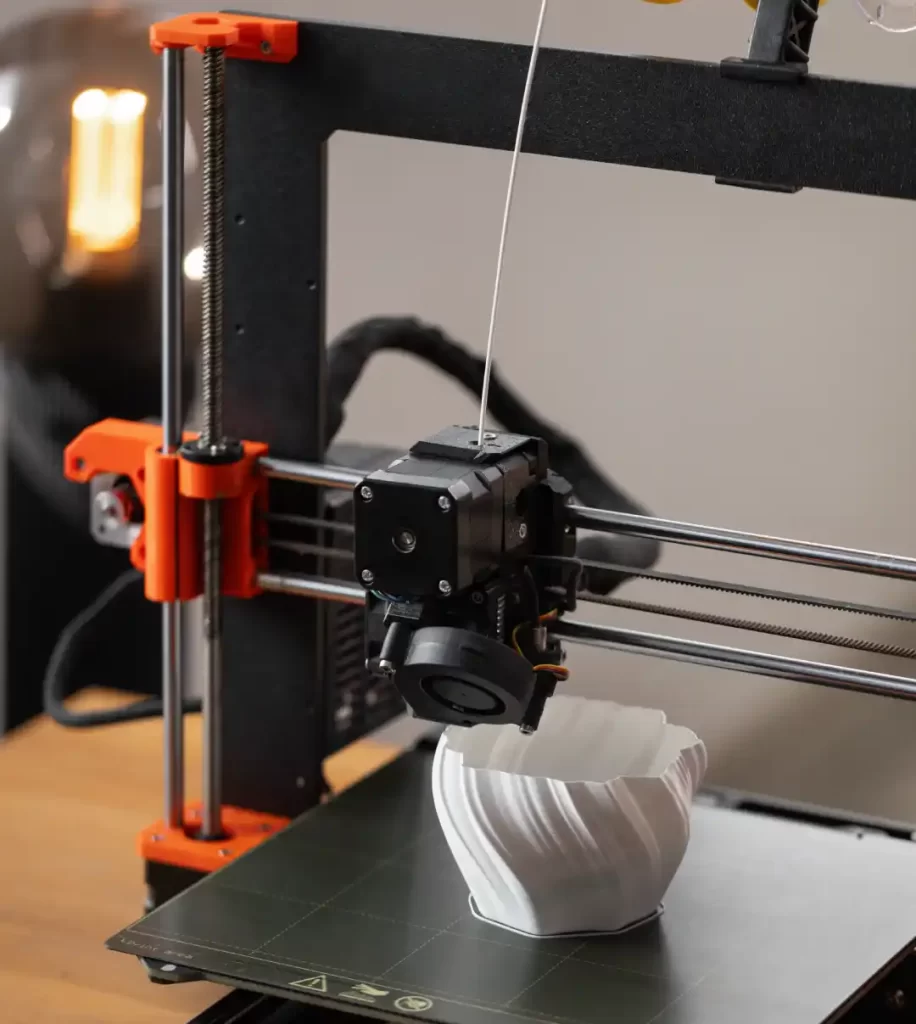

At Crystal Corporation LLC, we believe in educating our clients about the latest advancements in 3D printing technology. One such powerful technique that has revolutionized industrial manufacturing is Selective Laser Sintering (SLS)—a technology that plays a major role in additive printing across various industries.

While we currently specialize in FDM printing, resin printing, and custom 3D printing services in the UAE, we think it’s important for our audience to understand the broader landscape of 3D printing, including high-end technologies like SLS.

Understanding Selective Laser Sintering: A Key Technology in Additive Manufacturing

Selective Laser Sintering (SLS) is an advanced 3D printing process that uses a high-powered laser to fuse powdered materials (mainly plastic polymers) layer by layer to form solid, complex parts. It is widely used by high-performance 3D printing companies, especially in aerospace, automotive, healthcare, and product design.

This process is unique because it doesn’t require support structures — the unused powder itself supports the model during printing, making it ideal for geometrically complex and durable parts.

How Selective Laser Sintering Works

- A 3D model is prepared using CAD software or imported from a 3D print design platform.

- The printer spreads a thin layer of powder over the build platform.

- A laser scans and selectively sinters the powder based on the digital model.

- After each layer, the platform lowers and the process repeats until the part is complete.

- Excess powder is removed and can often be reused.

This method allows the production of strong, detailed, and functional prototypes or even end-use components.

Why Choose Selective Laser Sintering?

Here’s why many 3D printing firms and professionals choose SLS:

- Exceptional Strength & Durability

- No Need for Support Structures

- Excellent Surface Finish

- Ideal for Large and Complex Parts

Although SLS is typically more costly than FDM printing or resin-based 3D printing, it delivers unmatched quality for specific applications.

For budget-conscious projects, technologies like FDM printing — which we specialize in — offer a great balance between cost and functionality. Key factors that influence 3D printer printing cost include:

- Material type (plastic, resin, metal)

- Design complexity

- Model size

- Finishing and post-processing

Looking for 3D printing services in Dubai and the UAE?

At Crystal Corporation LLC, we proudly offer professional 3D printing services UAE-wide, including:

- FDM printing for prototypes and functional parts

- 3D resin printing for high-detail models

- Plastic 3D printing with excellent finish

- Custom 3D modeling for printing and design optimization

We help businesses and individuals bring their 3D print designs to life, offering efficient and cost-effective services. Whether you need a one-off piece or batch production, we’ve got the tools and expertise to deliver.

Partner with Crystal Corporation LLC

As a trusted 3D printing store and print shop based in the UAE, we work with clients across various industries to develop custom solutions that meet both technical and budgetary needs. While we do not currently offer metal 3D printing or SLS, we’re always happy to guide you toward the right process for your project.